I have visited dozens of hospitals over the past two years, spreading the gospel codified in the upper right-hand corner of this blog--patient-driven care, eliminating preventable harm, transparency of clinical outcomes, and front-line driven process improvement. My audiences are invariably polite and engaged, and I try to leave them with a sense of the possibilities before them. I know that some are inspired to take action, and some are not. I sometimes wonder if I make a difference. Is there a more useful way to spend my time?

And then I visit a place like Children's Mercy Hospital in Kansas City and get a jolt of renewed energy and optimism. And, lo and behold, they tell me that I help do the same for them. What karma!

I had a jam-packed day at CMH today. First, it was multidisciplinary

Grand Rounds, with a presentation to several hundred people in the auditorium and outlying facilities. Here's my host, Executive Vice President Karen Cox. The theme: "These Things Happen: How Harm Occurs in Hospitals and What We Can Do About It."

But then I got to see the team in action. I attended the Daily Safety Update, a short (9:10-9:30am) huddle of people from throughout the hospital reporting on operational matters and other issues that could affect patient safety. It is chaired by Jason Newland, medical director for safety, and Cheri Hunt, chief nursing officer (seen here).

One of the things that Lean organizations do is to promote and encourage standard work in clinical and operational settings. But managers have to engage in standard work, too. You may recall that Virginia Mason's COO,

Sarah Patterson, explained this when she discussed important aspects of daily management:

Elements of daily management = leader standard work + visual controls +

daily accountability process + discipline.

Whoa! Leader standard work, too! What a concept. Can't be "too busy"

for this!

With leader standard work made visible, staff now know, "Oh that's what

leaders do!"

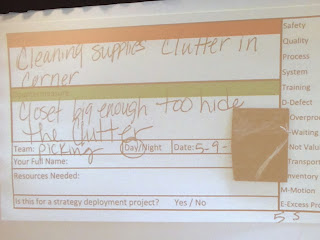

The CMH people have put this into place in a clear and effective way. All participants in the meeting orally fill in the chart of a daily operational report covering key areas. The reporting is efficient and direct, with areas of action set forth. For example, Rachael Dameron (above) presented data on the total number of ventilators in use in the various units of the hospital, staff on site last night and today, and any key events. Meanwhile Sherry McCool (below) reported on transport: How many runs in the last 24 hours, how many missed runs, how many delayed runs, and anticipated concerns for the next 24 hours.

The Daily Safety Update has created precursor and following events. Pre-huddles occur in the departments beforehand, so that the required data and status reports will be accurate. After the 20 minute meeting, subgroups will often coalesce to follow up on issues raised during the huddle.

CMH is not the only hospital that engages in this kind of huddle, but the process they use is as effective as any I have seen.

The rest of my morning was spent with people who work on programs to increase patient involvement in the hospitals' delivery of care. CMH has several family advisory boards, volunteers from the community who work with the hospital staff to help deliver more patient-centered care. Here, for example, you see DeeJo Miller, a family centered care coordinator, with Terrance Gallagher, a patient's father, who volunteers his time on one such FAB. DeeJo is one of the hospital's "parents on staff," paid people whose job functions include special attention to the needs of patients and families.

Among other things, DeeJo and her colleagues conduct educational programs for residents on the issue of patient- and family-centeredness. One part of that curriculum is to send residents on in-home visits, to see patients and families in their real life settings. She presented some verbatim reactions from some of the residents as their eyes were opened to life "out there." Here's a small sample:

Thoughts or concerns prior to your visit:

Looking forward to seeing a family's house. Dreading the fact that it was 2 hours. I didn't really know what I was supposed to do.

Tell us about you in-home visit:

It was more laid back than expected. the whole family was involved. Mom stated at the beginning that there is "no wrong way to ask a question." Helpful to talk to the sibling.

What strengths did you see in the family?

Amazing support among the siblings. "Supervised independence"--The parents let the daughter manage her diabetes; however, they always check on her and double check what she is doing. They do it in such a discreet way the daughter may not even realize that they are checking on her.

What surprised you the most?

Daughter was insulted by the doctor's attempt to equate her insulin pump to video game Mario Cart. She said it was "cheesy." High functioning children--they were more adult-like than kid-like. Don't remember what life was like before the diagnosis. child's openness, how much she knew and verbalized what she didn't want to talk about. Child's attitude mimicked Mom's attitude. The normalcy of it all.

What, if any, is the value of meeting in the home versus meeting somewhere else?

Made me think about the difference between just telling a family what to do and realizing how much work it takes to follow the instructions. Makes you think more about making sure that the family has what they need for home.

I sat admiringly through all these sessions, which demonstrated a thoughtful execution of the principles I mentioned at the start of this blog post. But I was even more impressed by the constant, "What do you think of this?" "Can we do it better?", questioning I received from the staff as the day went along. This is a group of people who are discontented with the status quo, who are modest about what they know and what they have accomplished, and who insist on getting better. I was told later than my visit gave them a shot in the arm, a reminder of what is possible, but it was actually they who did that for me. What a marvelous day with marvelous people!