I've been meaning to write about this for several months--ever since attending GBMP’s Northeast Shingo Prize Conference this past fall. Short version: You never know where you will see a superb example of process improvement. Read more for the details below.

The Center for Comparative Medicine at Massachusetts General Hospital has a mission of providing "the highest quality laboratory animal husbandry and veterinary services to MGH investigators and to ensure that all research animals at MGH are maintained and used in accordance with pertinent laws, regulations and accreditation standards." This is one of over 80 core facilities at Partners HealthCare System which are in place "to bring state-of-the-art instrumentation, methodologies and expertise crucial to the promotion of research on our campuses and beyond."

More specifically, the CCM works to:

(1) provide reliable, affordable, and responsive laboratory animal care and research services to MGH investigators in pursuit of scientific knowledge and medical breakthroughs for patients and their families;

(2) avoid or minimize pain and distress in animals under our care;

(3) maintain a fulfilling, respectful, and safe workplace for our employees.

The CCM has extensive facilities, including ventilated and static cages and racks, autoclaves, tunnel washers, rack washers, bedding dispensers, automatic watering (Edstrom), biosafety cabinets, cage changing stations. Services offered include procurement, husbandry, training, technical, import/export, quarantine, pathology, breeding, veterinary consulting, and customized research services to the MGH research community.

Hardly a place to find adherents to the Lean process improvement philosophy? No way. Meet Gerard Cronin, the "Kaizen Promotion Manager" at the CCM. As noted in this article by Bruce Hamilton:

CCM has been on its Lean journey for 8 years, and has adapted Lean tools and methods in novel ways to service their 5000 customers as efficiently as possible with a staff of 130 employees.

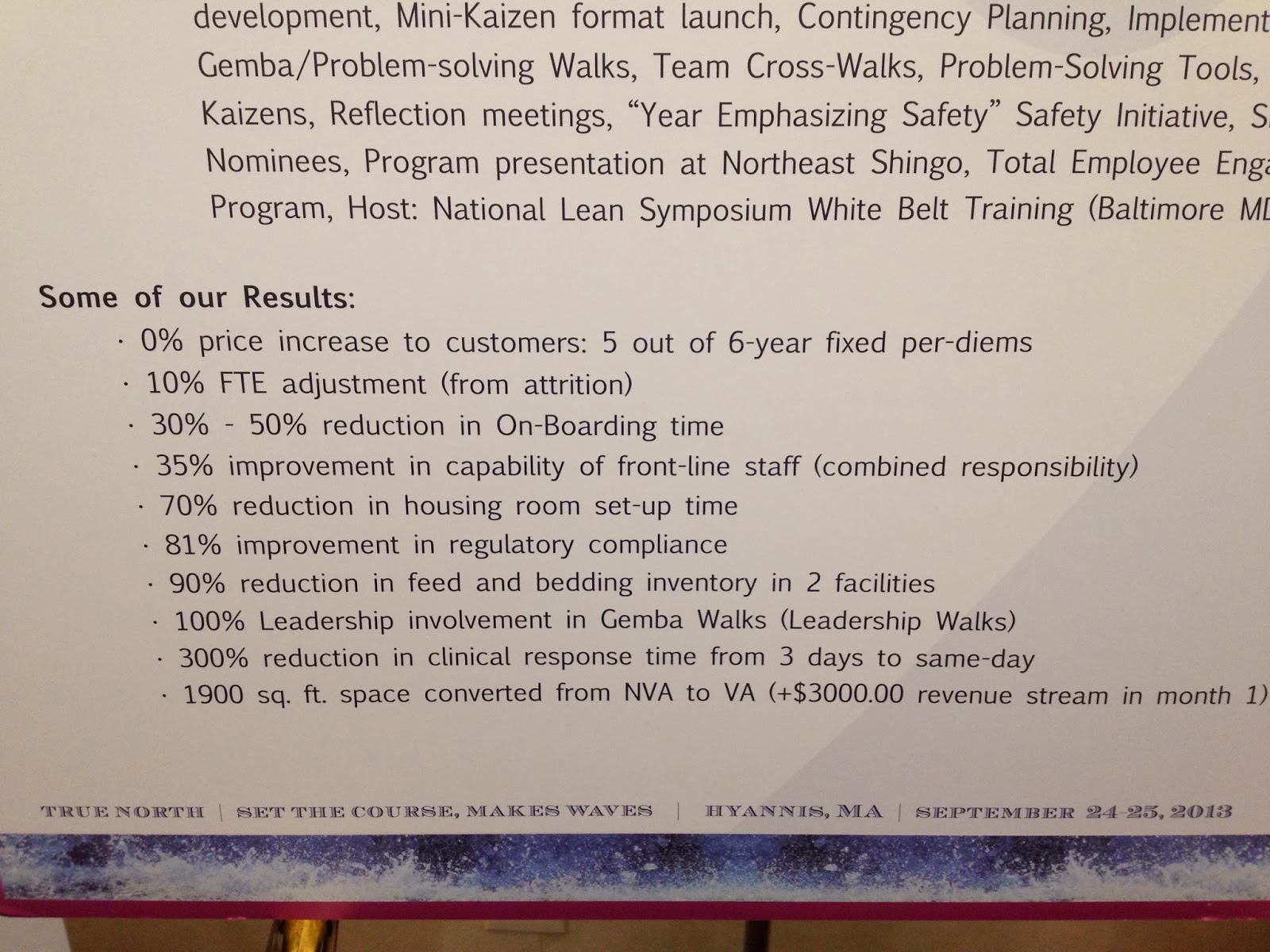

The results are stupendous, as seen in the accompanying summary.

Further:

As a pioneer in Lean management in Biomedical Research, CCM conducts Lean Tours, trainings and seminars to help accelerate the healthcare industry in the development of new therapies against disease.

At the Shingo conference's "Lean Lounge," many of us were drawn in by a kooky display of dangerous animals and props. Gerry and his able partner Julieanne Brandolini showed us the innovative pedagogical tools they use in their instructional sessions. They have created a "Lean Starter Kit" and other kits that teach people the standard work that should be in place in various circumstances.

Many conference attendees dropped by the display and stayed on for some time to learn from the good-natured presentations offered by Gerry and Julieanne. As Bruce noted in the article, "The theme of CCM’s 2013 Lean Lounge booth was 'if we can do it, anybody can.'"

True enough, but the leadership has to be in place to make it happen. This was one shining example of such leadership.

The Center for Comparative Medicine at Massachusetts General Hospital has a mission of providing "the highest quality laboratory animal husbandry and veterinary services to MGH investigators and to ensure that all research animals at MGH are maintained and used in accordance with pertinent laws, regulations and accreditation standards." This is one of over 80 core facilities at Partners HealthCare System which are in place "to bring state-of-the-art instrumentation, methodologies and expertise crucial to the promotion of research on our campuses and beyond."

More specifically, the CCM works to:

(1) provide reliable, affordable, and responsive laboratory animal care and research services to MGH investigators in pursuit of scientific knowledge and medical breakthroughs for patients and their families;

(2) avoid or minimize pain and distress in animals under our care;

(3) maintain a fulfilling, respectful, and safe workplace for our employees.

The CCM has extensive facilities, including ventilated and static cages and racks, autoclaves, tunnel washers, rack washers, bedding dispensers, automatic watering (Edstrom), biosafety cabinets, cage changing stations. Services offered include procurement, husbandry, training, technical, import/export, quarantine, pathology, breeding, veterinary consulting, and customized research services to the MGH research community.

Hardly a place to find adherents to the Lean process improvement philosophy? No way. Meet Gerard Cronin, the "Kaizen Promotion Manager" at the CCM. As noted in this article by Bruce Hamilton:

CCM has been on its Lean journey for 8 years, and has adapted Lean tools and methods in novel ways to service their 5000 customers as efficiently as possible with a staff of 130 employees.

The results are stupendous, as seen in the accompanying summary.

Further:

As a pioneer in Lean management in Biomedical Research, CCM conducts Lean Tours, trainings and seminars to help accelerate the healthcare industry in the development of new therapies against disease.

At the Shingo conference's "Lean Lounge," many of us were drawn in by a kooky display of dangerous animals and props. Gerry and his able partner Julieanne Brandolini showed us the innovative pedagogical tools they use in their instructional sessions. They have created a "Lean Starter Kit" and other kits that teach people the standard work that should be in place in various circumstances.

Many conference attendees dropped by the display and stayed on for some time to learn from the good-natured presentations offered by Gerry and Julieanne. As Bruce noted in the article, "The theme of CCM’s 2013 Lean Lounge booth was 'if we can do it, anybody can.'"

True enough, but the leadership has to be in place to make it happen. This was one shining example of such leadership.